Types of LTCS forged fittings

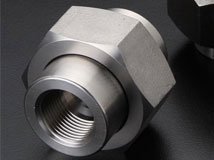

Fittings' end connections must align with pipe ends, either socket weld to plain end or NPT & BSP screwed end. Customized combined connections like socket weld x threaded are available upon request.

carbon steel forged fittings Manufacturing Standards

| ASTM A350 | ASTM specification for carbon and low-alloy steel forgings for pressure vessel components |

|---|---|

| ASTM A105/A105N | Standard specification for carbon steel forgings for piping applications, including flanges, fittings, and valves. |

| ASTM A694 | Specification for carbon and alloy steel forgings for pipe flanges, fittings, valves, and parts for high-pressure transmission service. |

| ASME B16.11 | Socket Welding and Threaded Forged Fittings |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

ASTM A105 Carbon Steel Forged Fitting Chemical Composition

| Element | Composition %, Note C |

|---|---|

| Carbon | .35 max |

| Manganese | .60-1.05 |

| Phosphorus | .035 max |

| Sulfur | .040 max |

| Silicon | .10-35 |

| Copper | .40 max, note A |

| Nickel | .40 max, note A |

| Chromium | .30 max, note A,B |

| Molybdenum | .12 max, note A,B |

| Vanadium | .08 max, note A |

| Note A – The sum of copper, nickel, chromium, molybdenum and vanadium shall not exceed 1.00% Note B – The sum of chromium and molybdenum shall not exceed .32% Note C – for each reduction of 0.01% below the specified carbon maximum (.35%), an increase of .06% manganese above the specified maximum (1.05%) will be permitted up to a maximum of 1.65% |

|

ASTM A105 Carbon Steel Forged Fitting Mechanical Properties

| Tensile | 70 ksi, min |

| Yield, note A | 36 ksi, min |

| Elongation in 2in, Basic minimum for wall 5/16″ and over, strip test | 30% |

| Hardness | 187 HBW max |

| Note A – Determined by either the 0.2% offset method or the 0.5% extension-under-load method. Other test methods available as listed in A105. | |

Equivalent Grades Of ASTM A350 Lf2 Fittings

| Material Group | Common Name | Material Type | UNS | Forging Spec. | Casting Spec. Equivalent | DIN | DIN W. No | Application |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel | CS | C-Si | K03504 | A105 | A216-WCB | C22.8 DIN 17243 | 1.0460 | General non-corrosive service from -29ºC (-20ºF) to 425ºC (800ºF) |

| Low Temperature Carbon Steel | LTCS | C-Mn-Fe | K03011 | A350-LF2 | A352-LCB A352-LCC | TSTE 355 DIN 18103 | 1.0566 | General non-corrosive service from -46ºC (-50ºF) to 340ºC (650ºF), LF2 -46ºC ~ 425ºC |

| Low Temperature Alloy Steel | Nickel Steel | 3.1/2Ni | K32025 | A350-LF3 | A352-LC3 | 10Ni14 | 1.5637 | -101ºC (150ºF) to 340ºC (650ºF) |

Low Temperature Carbon Steel Fitting Chemical Composition

| Element | Weight % |

| Carbon | 0.30 max |

| Silicon | 0.15 – 0.30 |

| Manganese | 0.6 – 1.35 |

| Phosphorus | 0.35 max |

| Sulphur | 0.040 max |

| Molybdenum | 0.12 max |

| Copper | 0.40 max |

| Chromium | 0.30 max |

| Nickel | 0.40 max |

| Vanadium | 0.08 max |

| Niobium | 0.02 max |