Pipe Spools Range

| Consturction | Size Range | Schedule / Thickness | |

|---|---|---|---|

| Min Thk (mm) | Max Thk (mm) | ||

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 48″ | 10s/8 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 24″ | 10s/3 mm | XXS/70 mm |

| Welded Fabricated | 0.5″ to 96″ | 10s/8 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 74″ | 10s/6 mm | XXS/70 mm |

Creative Piping is the premier exporter and distributor of ANSI / ASME B 36.10 & B 36.19 Pipe Spool Fittings, serving markets across the USA, UAE, Saudi Arabia, Oman, and Qatar.

Pre-Fabrication of Pipe Spools

Pre-fabrication of pipe spools involves assembling sections of piping, including pipes, fittings, and flanges, in a controlled environment before they are delivered to the job site. This process improves efficiency by reducing on-site labor, minimizing installation time, and ensuring precise quality control. Pre-fabricated pipe spools are widely used in industries like oil and gas, petrochemical, and power generation, where they facilitate the rapid and accurate construction of complex piping systems.

Why Pipe Spool with FBE Coating ?

Pipe Spools are fabricated by Pipe, Flanges, and Pipe Fittings. It is more convenient for installations and replacement; it doesn’t need any welding work. The pipeline might be jointed together by the flanges. It could save much time and price. FBE Coating Pipe Spool, it’s best to coating spool directly. If coating Pipe, Flanges, and Pipe Fittings, then welding them together, there is no coatings on welding part, and during welding, the coated area damaged.

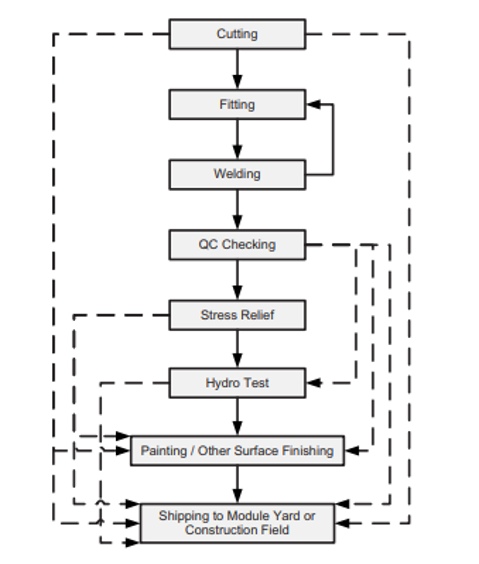

Manufacturing Process of ANSI / ASME B 36.10 & B 36.19 Pipe Spool