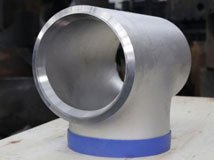

Types of nickel steel pipe fittings

Creative Piping is the premier exporter and distributor of nickel alloy equal, unequal or reducing cross buttweld fittings, serving markets across the USA, UAE, Saudi Arabia, Oman, and Qatar.

ASTM B366 Nickel Alloy Buttweld Fittings

| Trade Name | UNS # | Nickel Alloy Butweld Fittings |

|---|---|---|

| Alloy 20 | N08020 | B/SB366 Grade WP20CB |

| Nickel 200 | N02200 | B/SB366 Grade WPN |

| Nickel 201 | N02201 | B/SB366 Grade WPNL |

| Monel 400 | N04400 | B/SB366 Grade WPNC |

| Inconel 600 | N06600 | B/SB366 Grade WPNCI |

| Inconel 625 | N06625 | B/SB366 Grade WPNCMC |

| Incoloy 800 | N08800 | B/SB366 Grade WPNIC |

| Incoloy 800H | N08810 | B/SB366 Grade WPNIC10 |

| Incoloy 800HT | N08811 | B/SB366 Grade WPNIC11 |

| Incoloy 825 | N08825 | B/SB366 Grade WPNICMC |

The provided table exclusively pertains to WP Grade wrought buttweld fittings in accordance with ASME B16.9 standards. Notably, B/SB366 specifies permissible raw materials and manufacturing processes, enabling the production of these fittings. These fittings are marked with suffix class identifiers (S, W, WX, WU, and CR), mirroring A/SA403 requirements.