About ISO Flange Standard

The ISO (International Organization for Standardization) standard for flanges, specifically ISO 7005-1, establishes dimensions, materials, and performance requirements for flanges used in industrial piping systems worldwide. This standard ensures uniformity and compatibility across different manufacturers and regions, facilitating easier integration and maintenance of piping networks.

ISO flanges are categorized based on their nominal pressure (PN) ratings, which indicate the maximum allowable pressure at various temperatures. Common PN ratings include PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN320, and PN400, among others. These ratings help in selecting flanges suitable for specific pressure and temperature conditions within industrial applications.

ISO Flange Standard:

-

ISO 7005-1 Flange: This standard outlines dimensions and tolerances for metal flanges utilized in general industrial applications. It encompasses welding neck, slip-on, threaded, and blind flanges, each designed with specific pressure ratings and face types to ensure reliable performance in diverse environments.

-

ISO 7005-2 Flange: Part 2 of ISO 7005 focuses specifically on cast iron flanges. It provides detailed specifications for flanges, including dimensions, face types, and pressure ratings tailored to applications requiring the durability and corrosion resistance of cast iron materials.

-

ISO 2084 Flange Gaskets: Addressing non-metallic flat gaskets used with steel flanges, ISO 2084 sets standards for their dimensions and tolerances. These gaskets play a critical role in ensuring effective sealing in piping systems, enhancing safety and operational efficiency.

-

ISO 6162-1 and ISO 6162-2 Flange Connections: Known as SAE flanges, these standards define flange connections used in hydraulic systems. ISO 6162-1 covers flanges for pressures up to 35 MPa (5,000 psi), while ISO 6162-2 addresses higher-pressure applications up to 42 MPa (6,000 psi), ensuring robust performance in demanding hydraulic operations.

-

ISO 1609 Flange Facings: Providing guidelines for selecting flange facings, ISO 1609 ensures proper gasket seating and sealing in flanged joints. This standard helps optimize the integrity and reliability of flange connections across various industrial settings.

-

ISO 6182-1 Flange Pressure Relief Valves: This standard specifies the design and testing requirements for flanged steel pressure relief valves. It ensures these critical components operate effectively and safely in maintaining pressure levels within acceptable limits.

-

ISO 2531 Flange Joints: While primarily focused on ductile iron pipes, ISO 2531 also includes specifications for flanged joints used in pipe connections. It provides standards for ensuring secure and leak-free connections, essential for the reliable transport of fluids in water and wastewater systems.

ISO K Flanges (Vacuum Flanges)

-

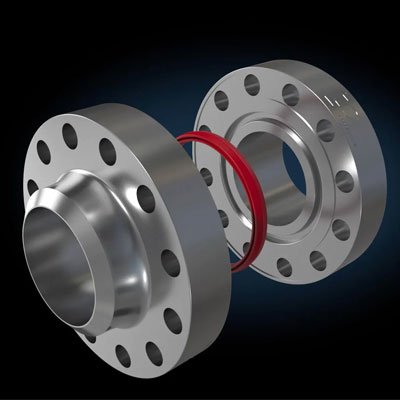

Purpose and Design: ISO-K flanges are engineered to create a reliable vacuum seal between components in vacuum chambers and systems. They feature a standardized flange face geometry and dimensions to ensure compatibility and interchangeability across different manufacturers.

-

Types and Variants: ISO-K flanges come in various types, including ISO-KF (quick flange) and ISO-K (large flange). ISO-KF flanges are smaller and often used in high-vacuum applications, while ISO-K flanges are larger and suitable for higher pressure differentials.

-

Key Features: These flanges typically include a centering ring with elastomer O-rings for sealing. The flanges are designed for easy assembly and disassembly, facilitating maintenance and component replacement in vacuum systems.

-

Applications: ISO-K flanges find applications in research and industrial settings where maintaining a clean, leak-free vacuum environment is essential. They are used in processes such as semiconductor manufacturing, particle accelerators, analytical instrumentation, and space simulation chambers.

-

Standards: ISO-K flanges adhere to ISO 2861 and ISO 1609 standards, which specify dimensions, materials, and sealing requirements to ensure optimal performance under vacuum conditions. Compliance with these standards ensures reliability, safety, and compatibility across vacuum systems globally.

ISO F Flanges (Vacuum Flanges)

-

Purpose and Design: ISO-F flanges are designed to create a robust and reliable vacuum seal between components in ultra-high vacuum (UHV) and high vacuum (HV) systems. They ensure airtight connections essential for maintaining low-pressure environments required in scientific research, semiconductor manufacturing, and space simulation chambers.

-

Types and Variants: ISO-F flanges typically feature a large diameter and a bolted design. They are available in various sizes ranging from small to large diameters to accommodate different vacuum chamber sizes and equipment configurations.

-

Key Features: These flanges are characterized by a flat sealing surface and a bolted clamp ring assembly that compresses a metal gasket (often made of copper) between mating flanges to achieve a vacuum-tight seal. They allow for easy assembly and disassembly, facilitating maintenance and component replacement in vacuum systems.

-

Applications: ISO-F flanges are used in critical applications where maintaining a clean, leak-free vacuum environment is essential. They are employed in particle accelerators, synchrotron facilities, electron microscopes, thin film deposition systems, and other high-tech industries requiring precise vacuum conditions.

-

Standards: ISO-F flanges adhere to international standards such as ISO 1609 and ISO 3669, which specify dimensions, materials, and sealing requirements to ensure optimal performance under vacuum conditions. Compliance with these standards ensures reliability, safety, and compatibility across vacuum systems globally.

ISO 6162 Flanges (Hydraulic Flanges)

-

Standards: ISO 6162 adheres to international standards that specify dimensions, pressure ratings, and performance requirements for hydraulic flanges. Compliance with these standards ensures compatibility and interchangeability of components from different manufacturers.

-

Purpose and Application: ISO 6162 flanges are designed to withstand high-pressure hydraulic applications. They provide a robust and leak-free connection, essential for fluid power systems operating under demanding conditions.

-

Types and Variants: ISO 6162 is divided into two parts:

- ISO 6162-1: Covers flanges for nominal pressures up to 35 MPa (5,000 psi). These are commonly used in medium-pressure hydraulic systems.

- ISO 6162-2: Addresses flanges for nominal pressures up to 42 MPa (6,000 psi), suitable for high-pressure hydraulic applications.

-

Design Features: These flanges feature a four-bolt pattern with a flat face or an O-ring groove face design, ensuring a tight seal and preventing leaks under high pressure. They allow for easy assembly and disassembly, facilitating maintenance and component replacement in hydraulic systems.

-

Materials and Construction: ISO 6162 flanges are typically made from materials such as carbon steel, stainless steel, and other alloys to withstand corrosion and mechanical stresses encountered in hydraulic operations.

As a premier exporter and distributor, Creative Piping Solutions delivers ISO 7005-1 Flange to markets Including the USA, UAE, Saudi Arabia, Oman, and Qatar.