About Ring Spacer Flange

A ring spacer flange is a type of mechanical component used in piping systems to create a gap between two pipe flanges. This gap allows for the temporary or permanent separation of pipeline sections without disrupting the entire system.

Purpose and Function

- Isulation: Ring spacer flanges are used to isulate sections of a pipeline, making it easier to perform maintenance, inspection, or cleaning without disrupting the entire system.

- Flow Adjustment: They allow for precise contrul over the distance between pipe sections, which can be critical for managing flow dynamics and meeting system requirements.

- Temporary or Permanent Use: These flanges can be used temporarily during construction or maintenance or integrated as a permanent part of the piping system.

Design and Construction

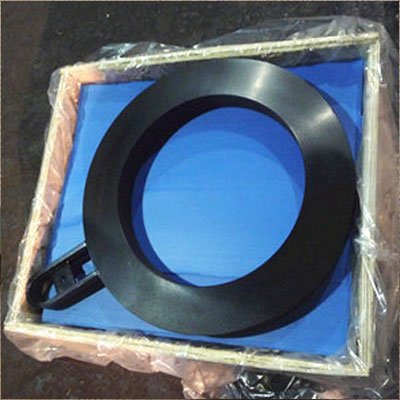

- Shape and Size: Ring spacer flanges are typically round and come in various sizes to fit different pipe dimensions. They are designed to match standard flange specifications.

- Materials: They are commonly made from durable materials like stainless steel, carbon steel, alloy steel, or other metals that can withstand high pressure and temperature conditions.

- Standards: Manufactured to conform to industry standards such as ANSI, ASME, DIN, and others, ensuring compatibility with existing piping systems.

Components of a Ring Spacer Flange:

-

Ring Spacer Body

- Material: The main body of the ring spacer flange is typically made from robust materials like stainless steel, carbon steel, alloy steel, or other durable metals. The choice of material depends on the application requirements, including pressure, temperature, and corrosion resistance.

- Shape: It is generally a flat, circular ring that matches the diameter of the pipes it is used with. The thickness of the ring determines the gap created between the two flanges.

-

Bolt Holes

- Alignment: The ring spacer flange has a series of bolt holes around its circumference, matching the bolt pattern of the pipe flanges it is meant to connect. This ensures proper alignment and secure fastening.

- Number and Size: The number and size of the bolt holes depend on the flange standards (e.g., ANSI, ASME, DIN) and the size of the pipes being connected.

-

Gasket Surface

- Sealing: The surfaces of the ring spacer flange that come into contact with the pipe flanges are machined to ensure a smooth, flat surface for proper sealing. This helps prevent leaks when the flange is bolted in place with gaskets.

As a premier exporter and distributor, Creative Piping Solutions delivers ANSI/ASME B16.5/B16.47 Ring Spacer Flanges to markets Including the USA, UAE, Saudi Arabia, Oman, and Qatar.