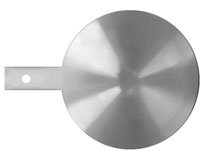

SS 304L Flanges types

Buy SS 304 Flanges and SS 304L/ 304H Ring Type Joint Flanges With An Outer Diameter Of 19mm-102mm as per ASTM A182

Stainless steel 304L Flanges chemical composition

| C | Mn | Si | P | S | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.07max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 | min: 8.0 max: 10.5 | — |

| 304L | 0.03max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 | min: 8.0 max: 12.0 | 0.10 max |

| 304H | min: 18.0 max:20.0 |

min: 8.0 max: 10.5 |

min: 0.04 max:0.10 |

0.75 max |

2.0 max |

0.045 max |

0.03 max |

0.10 max |

Stainless steel 304 Flanges mechanical properties

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 304 | 75 | 30 | 40 | 201 | 92 |

| 304L | 70 | 25 | 40 | 201 | 92 |

| 304H | 75 | 30 | 40 | 201 | 92 |

Stainless steel 304H Flanges equivalent

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| SS 304 | S30400 | 1.4301 | Z7CN18‐09 | X5CrNi18-10 | SUS 304 | 304S31 | 08Х18Н10 |

| SS 304L | S30403 | 1.4306/1.4307 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 304S11 | 03Х18Н11 |

| SS 304H | S30409 | 1.4301 | - | - | - | - | - |

ASTM A182 F304 Flanges physical properties

| SS 304/304L | ||||||

|---|---|---|---|---|---|---|

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 10.2 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 10.4 at 32 – 1500°F | |||||

| SS 304H | ||||||

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | ||

| at 68 °F | at 68 – 212°F | at 68 – 1600°F | at 212°F | at 932°F | at 32 – 212°F | in tension (E) |

| 0.285 | 9.2 | 11.0 | 9.4 | 12.4 | 0.12 | 29 x 106 |