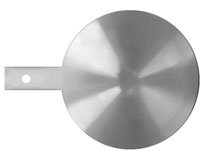

SS 317L Flanges types

Buy SS 317 Flanges and SS 317L Spectacle Blind Flange, Paddle Blind, and Ring Spacer With An Outer Diameter Of 19mm-102mm as per ASTM A182

Stainless steel 317L Flanges chemical composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

Stainless steel 317 Flanges mechanical properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless steel 317L Flanges equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

|---|---|---|---|---|

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |